Automatic Patty Forming Machine

Automatic Patty Forming Machine can automatically perform various procedures such as meat filling, forming and outputting, and combinea fully automatic prepared food line when connecting with the batter, preduster, fryer, cooker, instant freezer and packing machine.

Automatic Patty Forming Machine can widely handles in the forming procedure of meat, poultry, fish, shrimp and the potato, tuber crops.

Automatic Patty Forming Machine Suitable for the forming of raw materials such as meat, fish and vegetables.The product section presents the meatloaf, the attractive feeling of the meat fiber, which is popular with consumers.

Henco Commitment And Service

① Factory direct sales

② Worldwide shipping

③ ODM and OEM

④ 24/7 support

Product Description

Product brief introduction

Automatic Patty Forming Machine can automatically perform various procedures such as meat filling, forming and outputting, and combinea fully automatic prepared food line when connecting with the batter, preduster, fryer, cooker, instant freezer and packing machine.

Automatic Patty Forming Machine can widely handles in the forming procedure of meat, poultry, fish, shrimp and the potato, tuber crops.

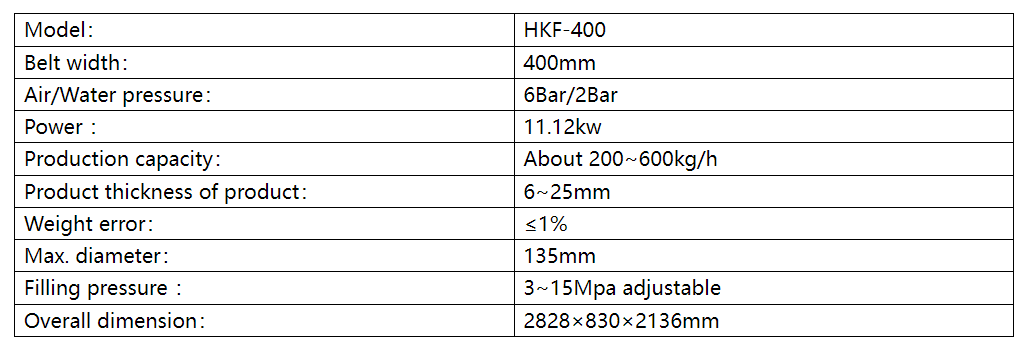

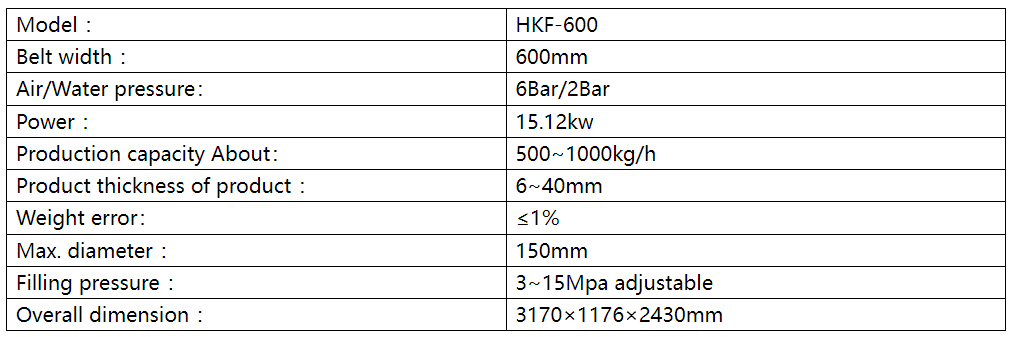

Parameters

Product features and applications

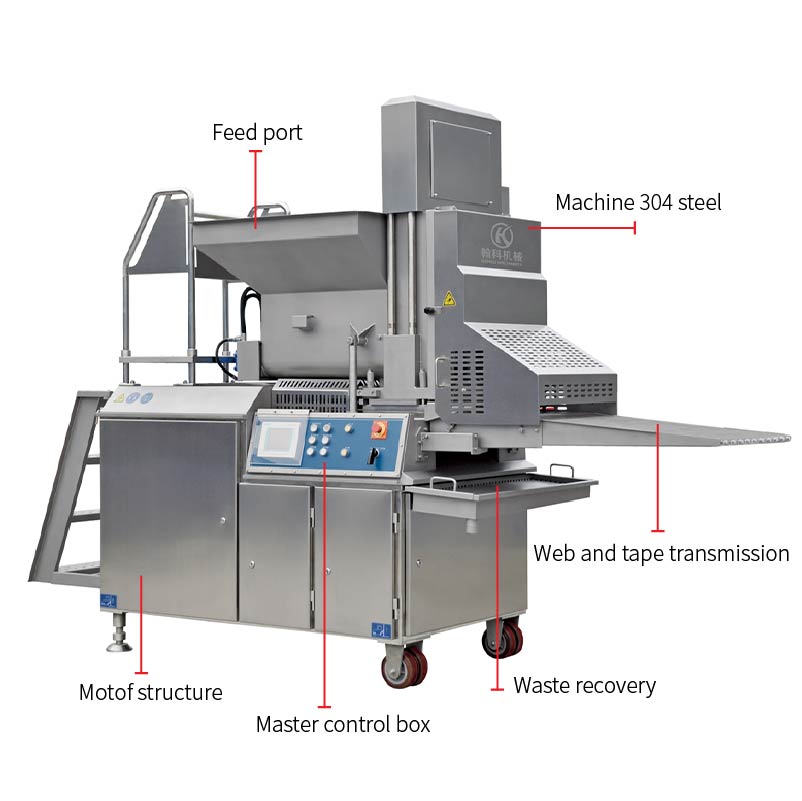

1. The use of disc extrusion technology, combined with process requirements, makes the product beautiful appearance, uniform size, bright and delicate surface, smooth taste, good elasticity and toughness.

2. The feeding surface and filling are made of quad dragon structure, and the digital frequency conversion control can adjust the conveying amount of the surface filling and the weight of the finished product.

3. The main parts are made of stainless steel and aluminum alloy materials, beautiful appearance, in line with food hygiene standards.

4. Reasonable structure, forming, inlet and control board are driven by independent motor, not easy to occur joint failure, and easy maintenance, disassembly and cleaning.

Product details and multi-directional display

1. Screw conveyor. The method of four-screw feeding system greatly reduces the cutting of materials, and has the characteristics of high production capacity and stable quality.

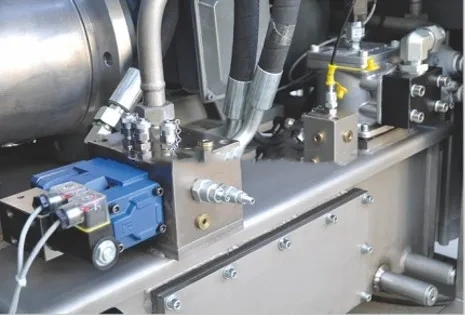

2. Hydraulic system. Hydraulic parts: Using Vickers, Stauf, Parker, comprehensive hydraulic original parts to ensure stable operation of the whole machine.

3. Filling system. Extensive processing of meat, poultry, fish, shrimp and potatoes, tuber crop molding process. It can be applied to a variety of chopped/sliced product areas to obtain superior meat texture.

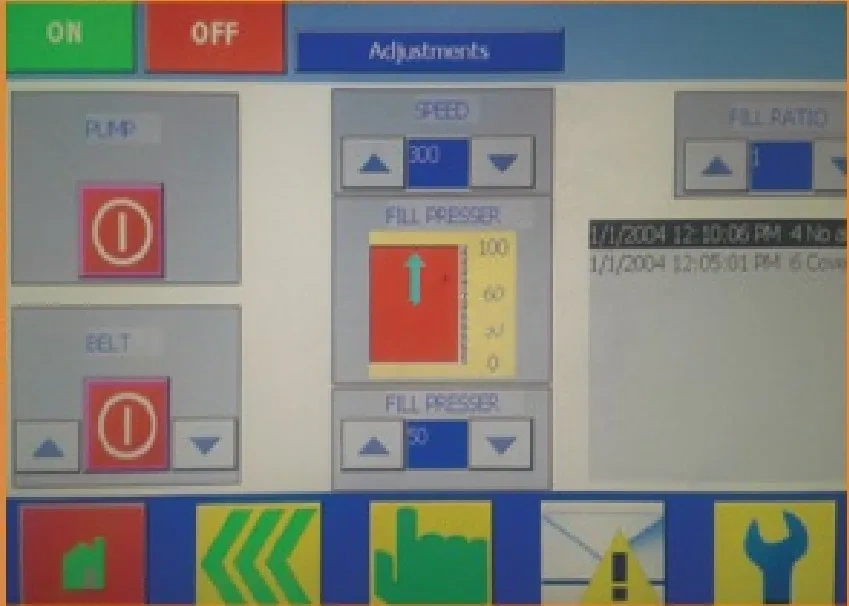

4. Touch screen operating system. Electrical parts: original Siemens PLC processor, touch screen operation, Chinese/English operating system and automatic fault alarm system.

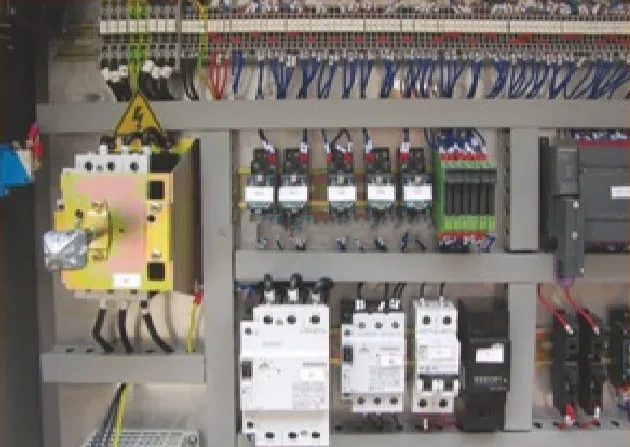

5. Electrical equipment parts. Stainless steel materials and some non-metallic materials, safe and reliable, in line with the standard HACCP, and authorized by the Chief Executive. Safety device: magnetic protection switch (safety cover).

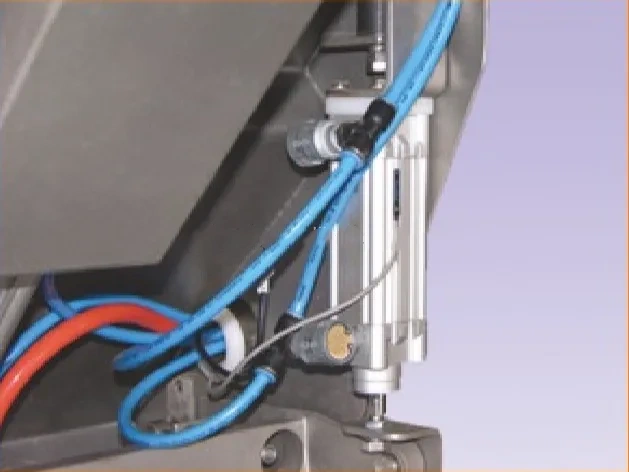

6.Pneumatic parts. Pneumatic system: Complete German FESTO original system.

منتجات ذات صلة

-

آلة تشكيل الطعام

Automatic Beet Chicken Shredding Flouring Machine(Meat Shredding Machine)

تم التقييم 0 من 5قراءة المزيد