Harinadora automática de tambor para alimentos

$21,000.00 El precio original era: $21,000.00.$20,000.00El precio actual es: $20,000.00.

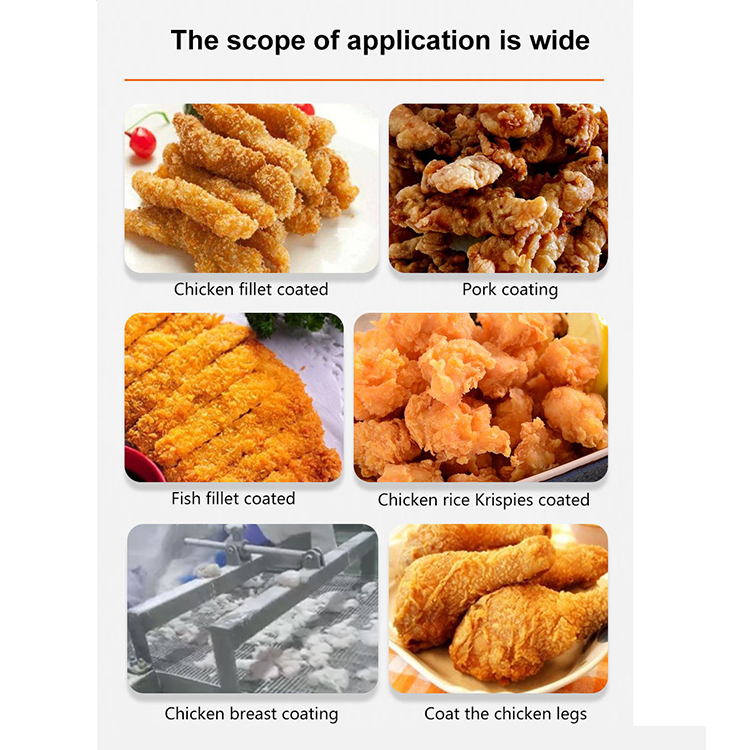

Food Drum Flouring Machine provides coating on irregular shaped products such as shrimp, poultry, mushrooms, popcorn chicken, chicken mass, fish mass etc., and increase the quantity of the flour on the products surface. It provides equal and uniform coating on all surfaces by the turning box and can also be used to apply free-flowing flour as well as breading for pre-dusting.

Henco Commitment And Service

① Factory direct sales

② Worldwide shipping

③ ODM and OEM

④ 24/7 support

Descripción del producto

Product Introduction

Automatic Food Drum Flouring Machine By the turning of the tumbling box, it can coat the products with even layer of the coating flour; increase the quantity of the flour on the pr- oducts surface. It causes the obvious scaly food surface. It is used for the massive products flouring and breading processing. Such as chicken nuggets, Popcorn Chicken, fish nuggets etc.

Food Drum Flouring Machine provides coating on irregular shaped products such as shrimp, poultry, mushrooms, popcorn chicken, chicken mass, fish mass etc., and increase the quantity of the flour on the products surface. It provides equal and uniform coating on all surfaces by the turning box and can also be used to apply free-flowing flour as well as breading for pre-dusting.

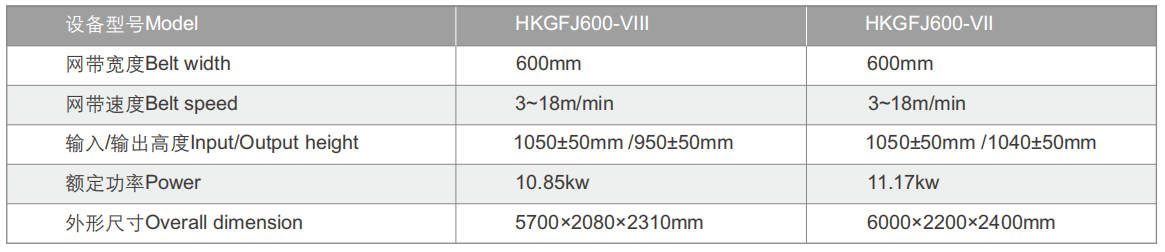

Product Parameters

Product Features and Applications

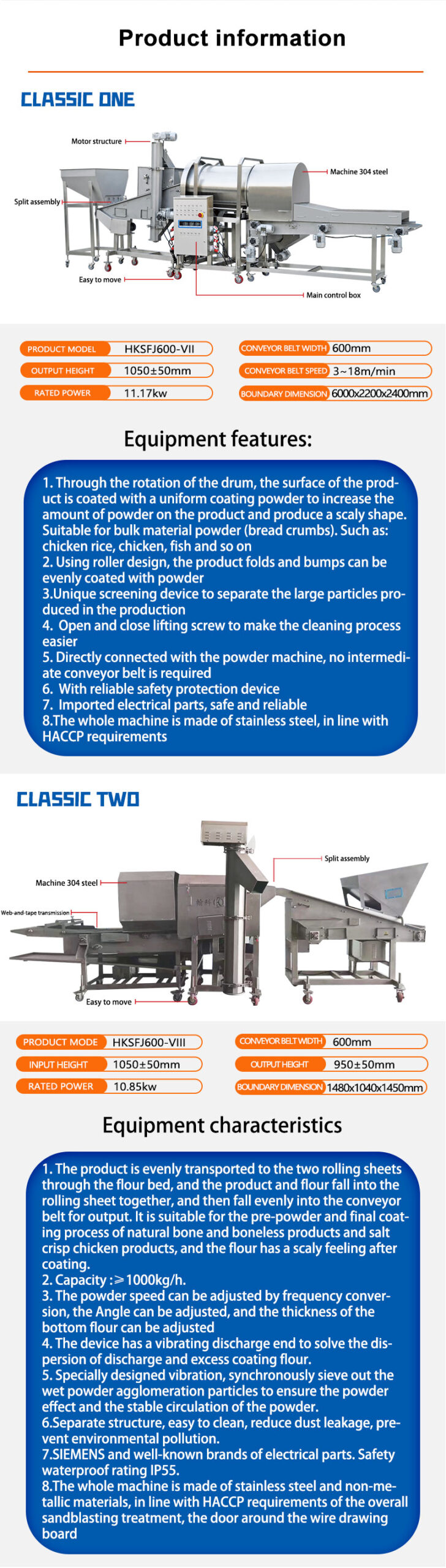

The latest external cycle drum powder machine includes:

1. A pre-loading powder machine, the transmission network with powder, powder on the top, the cured product falls on the powder (the old model after curing the material directly and the conveyor belt contact, no sticky conveyor soup loss problem).

2. One powder system on the roller (the products wrapped in powder are evenly separated in the roller, and the powder is more uniform once again).

3. A vibrating net belt machine (the products out of the roller are evenly dispersed through the main transmission vibrating net belt machine, without adhesion, and the excess powder is returned to the output spiral).

4. A vibrating screen (pass the wet powder through the vibrating screen, screen out the large particles, and return the fine powder to the first pre-loading machine to form an external circulation).

Product details Multi-directional display

1. Roller powder. Due to the roller design, the folds and bumps of the product can also be evenly coated with powder.

2. Screening device. A special screening device separates the large particles produced during the production process.

3. Loading conveyor belt. Imported Interle module belt, easy to disassemble, easy to clean.

4. Simple operation. With reliable safety protection devices, SIEMENS electrical parts are safe and reliable.

Productos relacionados

-

Aplicador de harina alimentaria

Intelligent Food Flat Flouring Machine(Preduster Flouring Machine)

Valorado con 0 de 5Leer más