自動インテリジェントアイスコーティングマシン

It is suitable for the prepackaging of frozen food, which can form a uniform layer of ice coating on the surface of the product to reduce the loss of water during the refrigeration process and ensure the fresh and tender meat quality of the product.

ヘンコのコミットメントとサービス

工場直販

全世界への発送

ODM および OEM

年中無休のサポート

商品説明

製品概要

Ice coating machine is a device used for product preservation and weight gain after freezing, which is convenient for products to enter the cold storage after freezing. The Ice coating machine is mainly used in the rapid ice packing of frozen products, the machine adopts the way of mesh belt conveying, the material is transported to the high pressure spray device, so that the material can be completely hung ice, and the ice hanging effect is good.

Product parameter

| モデル | HKBYJ600 |

| ベルト幅 | 600mm |

| ベルト速度 | 5~25m/min adjustable |

| Input/Output height | 800±50mm /800±50mm |

| パワー | 0.65kw |

| 全体寸法 | 1460×750×1160mm±50mm |

製品の特徴と用途

1.Ice coating machine is to mix water and air to form a mist spray to the surface of the product, so that the surface of the product to form a uniform layer of ice coating. Thus reduce the loss of water in the refrigeration process and ensure the fresh and tender meat quality of the product.

2.The spray is uniform, and the ice coating thickness can be adjusted by 2-5%. Safety waterproof rating IP65

3.Made of stainless steel and non-metallic materials that meet food requirements.

4.Suitable for uniform coating of chicken breast, beef, pork, fish, vegetables and other products.

製品詳細 多方向ディスプレイを導入

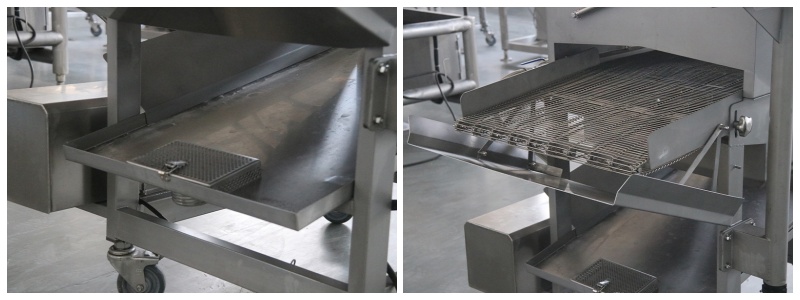

1.Spray evenly; Can make the product weight increase 2~5%.

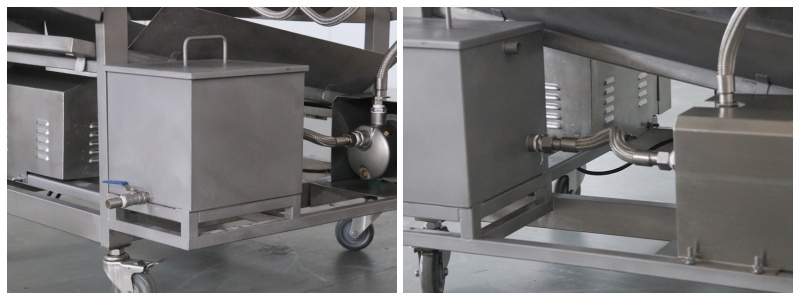

2.Waste recycling, keep the production environment clean and reduce waste.

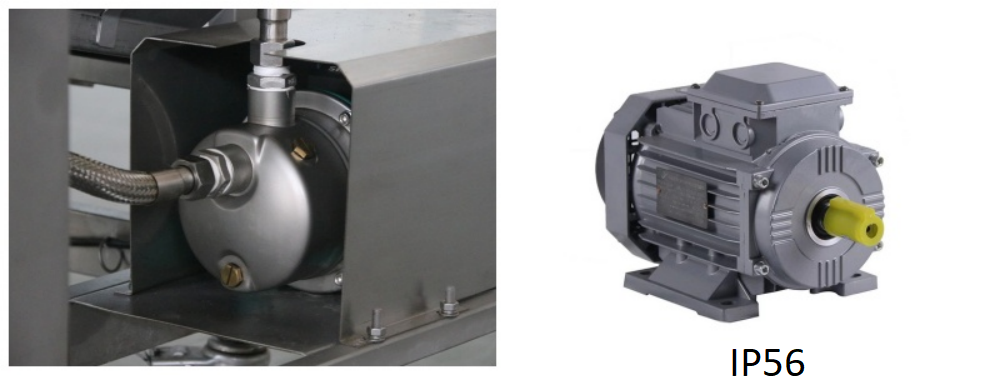

3.Motor waterproof grade IP56, full speed operation 790 times /min, can be washed with water, warranty 1 year, bad replacement machine.

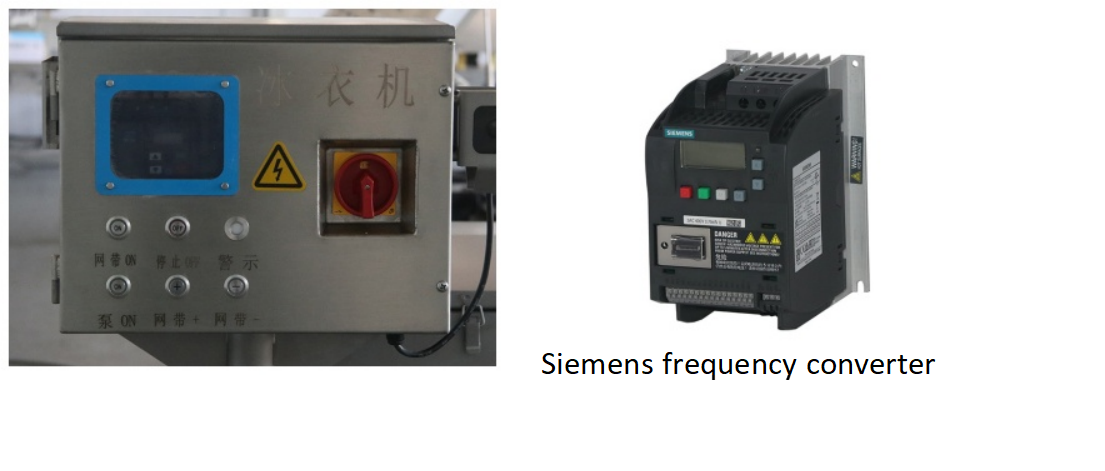

4.Siemens inverter can adjust the speed of the conveyor belt, and has a self-protection system, when the current and voltage are abnormal, the machine automatically stops and displays the fault code to avoid burning electrical parts and motors.

5.Water storage tank design to cope with a variety of unexpected situations to ensure product quality.