Automatic Beet Chicken Shredding Flouring Machine(Meat Shredding Machine)

At present, the cooked chicken breast processing into silk factory is generally torn by hand, the efficiency is slow, and the labor intensity is relatively large, there are also factories with machines to beat the wire, but the cost is more, and the product is easy to form accumulation, not good discharge, in view of this situation, the existing wire machine has been improved design.

ヘンコのコミットメントとサービス

工場直販

全世界への発送

ODM および OEM

年中無休のサポート

商品説明

製品概要

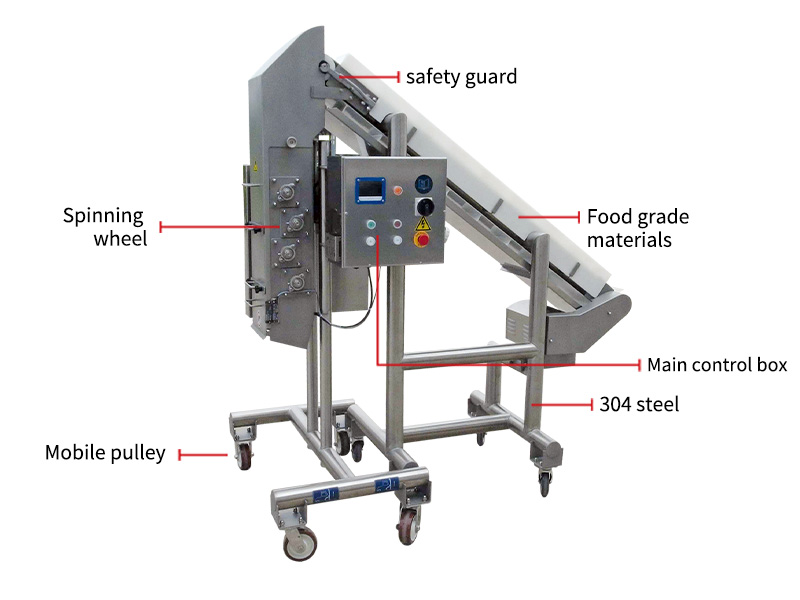

Meat shredding machine provide a fast, clean and versatile solution for producing pulled and shredded cook meats such as cooked chicken breast, pork and beef quickly and efficiently.

Made for use in restaurants, at home, hotels, industrial kitchen, cafeteria, delicatessens, butcher shops, grocery stores and more. VER Meat shredding machine is the most time saving and maximum output giving. Our machines allow your employees time to be utilized in many different areas and tasks resulting increasing the productivity and profit.The design is unique and built with stainless steel along with standard warranty.

Meat shredding machine for By rotating four sets of rollers, cooked chicken, pork, and beef can be shredded into a hand-torn fiber, which can easily break tough products such as cooked beef and soft products such as cooked chicken breast.

Product parameter

| モデル | HKDSJ400 |

| Max. meat length | 200mm |

| Max. meat width | 250mm |

| Max.speed | 4m/min |

| パワー | 1.5kw |

| 全体寸法 | 2980mm×1000mm×2000mm |

製品の特徴と用途

1.Whether it is cooked beef with full tenacity or soft cooked poultry, the ideal filamentary product will be obtained through the device.

2.High degree of automation, can make your production of products like artificial hand-torn fiber effect, better quality.

3.Safe and reliable, through the safety switch to avoid high-speed rotating parts of the human hand damage.

4.Suitable for chicken breast, beef, pork, etc.

製品詳細 多方向ディスプレイを導入

1. Excellent security protection to ensure your safety.

2.Split structure, easy to move and disassemble.

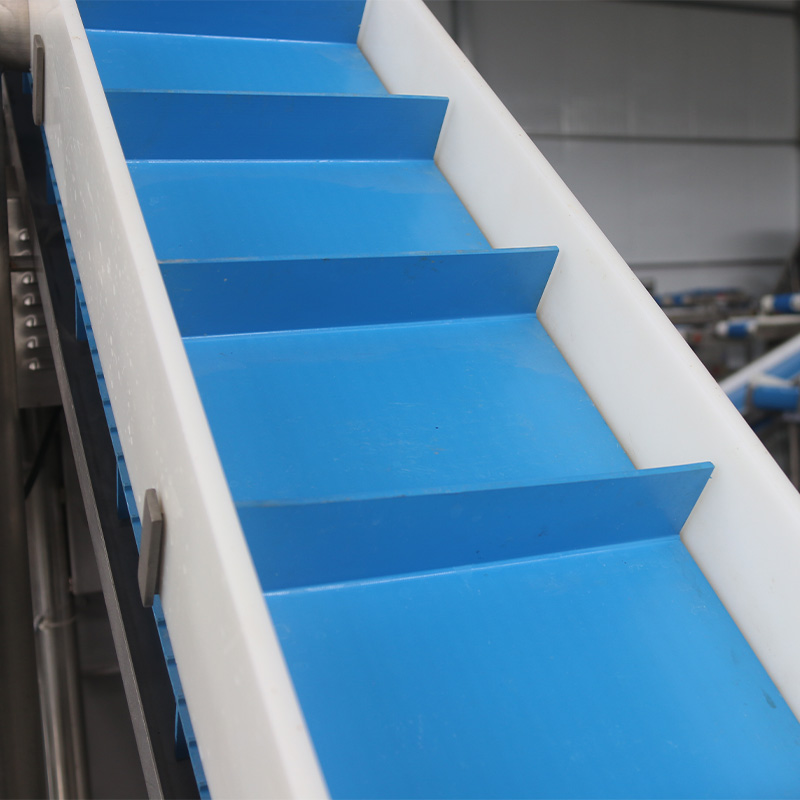

3.Food grade manufacturing materials provide the basic guarantee for the food safety of your products.

4.Siemens inverter can adjust the speed of the conveyor belt, and has a self-protection system, when the current and voltage are abnormal, the machine automatically stops and displays the fault code to avoid burning electrical parts and motors.

5.All oil-free bearings imported from Germany.